- Chapter 1: Common Noise Sources Across Key Industries

- Chapter 2: The Real Cost of Uncontrolled Noise

- Chapter 3: Understanding Frequencies and Measurement

- Chapter 4: Key Acoustical Ratings for Industrial Applications

- Chapter 5: Noise Regulations and Compliance

- Chapter 6: Choosing the Right Noise Control Solutions

- Chapter 7: Partnering with Noise Control Professionals

- Chapter 8: Get Expert Help With Your Noise Control Needs

Effective noise control can be the difference between success and unexpected delays, costs, and community complaints.

This handbook provides practical guidance on how to get it right the first time. You’ll learn why different industries face unique acoustic challenges, how professionals measure and regulate sound effectively, and how to select solutions that actually work for your specific situation.

Whether you’re managing a pipeline project, operating a processing facility, or developing new infrastructure, this guide provides the foundation for making informed noise control decisions.

Common Noise Sources Across Key Industries

Industrial noise isn’t just an annoyance — it’s a complex challenge that affects worker health, regulatory compliance, community relations, and your bottom line. Understanding where noise originates in your industry and why controlling it matters is the first step toward effective mitigation.

Oil and gas operations face the challenge of continuous, high-decibel operations often near residential areas. The unique difficulty lies in managing 24/7 operations. Pipeline compressor stations are a great example of this challenge — they must operate continuously but often sit near communities that didn’t exist when the infrastructure was originally built.

Data centers deal with persistent low-frequency noise that travels much farther than traditional industrial noise. The challenge isn’t peak decibel levels but rather the constant, monotonous hum that becomes increasingly irritating to neighbors over time.

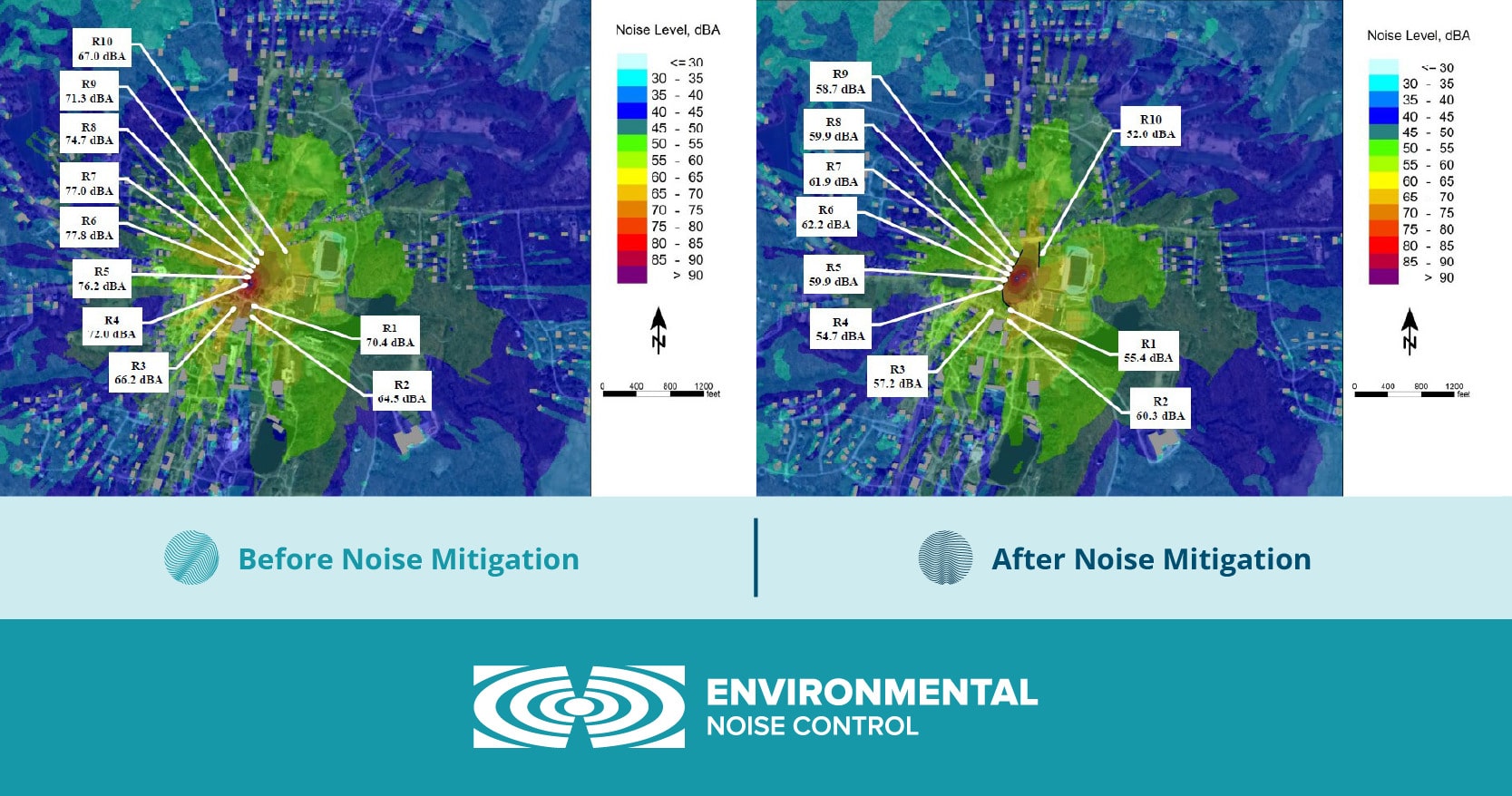

Entertainment venues must balance conflicting acoustic needs — creating optimal sound experiences while containing noise within property boundaries. The unique challenge lies in managing highly variable sound levels and frequencies, from deep bass that travels through solid structures to high-frequency sound that carries across neighborhoods.

Construction sites face different noise challenges as projects progress through different phases. Urban sites face the added complexity of working within strict time windows while maintaining productivity.

Industrial manufacturing facilities often struggle with cumulative noise from multiple operations. They also face the challenge of protecting workers’ hearing in large, echoey facilities.

Directional drilling operations must often manage intensive, short-term noise impacts in urban environments. The unique challenge is compressing traditional drilling timelines while meeting stricter noise limits and potentially 24/7 operations.

Environmental services face the challenge of protecting wildlife from loud but necessary operations. Traditional noise barriers don’t always work with endangered habitats, so they must use wildlife-friendly solutions.

The Real Cost of Uncontrolled Noise

Worker Safety and Health

The CDC estimates that 22 million workers are exposed to potentially damaging noise at work each year. Current data shows that approximately 12% of all workers have hearing difficulty, with about 8% suffering from tinnitus. When your crew can’t hear warning signals or communicate clearly during critical operations, safety incidents become more likely.

The effects extend far beyond hearing loss as well. Workers in high-noise environments report higher stress levels, increased fatigue, and difficulty communicating effectively — all factors that contribute to workplace accidents. Repeated overexposure to noise at or above 85 dBA is also associated with cardiovascular disease, depression, and balance problems.

Regulatory Compliance

Most jurisdictions have specific noise regulations for industrial operations. Violations can result in stop-work orders, fines, and lengthy permit delays. More importantly, repeated violations can damage relationships with regulatory agencies, making future projects difficult to approve.

Community Relations and Project Continuity

Community noise complaints can derail even well-planned projects. A single upset neighbor with influence or persistence can trigger regulatory investigations, media attention, and legal challenges that cost far more than proactive noise control. Projects that start with good community relations and maintain them through effective noise management typically face fewer delays and obstacles.

Understanding Frequencies and Measurement

Effective noise control starts with understanding how sound behaves and how we measure it. Without this foundation, you might invest in solutions that look good on paper but fail to address your actual noise challenges.

How We Measure Sound

Sound measurement involves two key concepts: volume and frequency. Volume tells us how loud something is, while frequency tells us the pitch or tone. Both matter tremendously for noise control because our ears — and our neighbors — respond differently to different combinations.

Frequency Ranges and Industrial Sources

Understanding frequency ranges helps you match the right solution to your specific noise signature:

- Low-frequency sounds (20-250 Hz): Diesel generators, compressors, HVAC systems, heavy machinery vibrations. These frequencies travel farther and penetrate buildings more effectively than higher frequencies.

- Mid-frequency sounds (250-2000 Hz): Most machinery noise, power tools, equipment alarms. This range includes frequencies critical for speech communication and workplace safety.

- High-frequency sounds (2000+ Hz): Pneumatic tools, metal-on-metal contact, steam releases, electronic equipment. These frequencies are often the most immediately annoying, but don’t travel as far.

Decibels and Weighting Systems

Decibels (dB) measure sound intensity, but raw decibel readings don’t tell the complete story. That’s why we use weighted measurements that account for how humans actually perceive sound. Understanding the difference between dBA and dBC measurements is crucial for compliance and community relations.

dBA (A-weighted decibels) mimics how the human ear perceives sound, emphasizing the frequencies we hear most clearly. Most noise regulations use dBA limits because they correlate with human comfort and hearing damage risk.

dBC (C-weighted decibels) captures the full frequency spectrum, including low-frequency bass that humans feel more than hear. This measurement is critical for entertainment venues and operations with diesel generators or heavy machinery that produce significant low-frequency energy.

The distinction matters because you might be compliant with dBA limits while still generating noise complaints from low-frequency rumble that travels through buildings. Los Angeles’ Hollywood Bowl, for example, must maintain both 95 dBA and 108 dBC limits to address both heard and felt sound.

Key Acoustical Ratings for Industrial Applications

Professional noise control relies on two primary performance metrics that measure different aspects of sound management.

Sound Transmission Class (STC)

STC ratings tell you how effectively a material blocks sound from passing through. It’s reflected in a number value, typically from 25 to 65+. You might think, the higher the number the better, but performance varies dramatically by frequency. The same STC-25 barrier might reduce 100 Hz diesel generator noise by only 11 dB while reducing 1000 Hz equipment noise by 39 dB.

Noise Reduction Coefficient (NRC)

NRC ratings, on the other hand, measure how much sound a material absorbs rather than blocks. NRC ranges from 0 (no absorption) to 1 (perfect absorption). A material with NRC 0.75 absorbs 75% of sound energy that hits it while reflecting 25% back into the space.

Understanding NRC is crucial because reflective surfaces can create acoustic “hot spots” where sound levels actually increase due to reflected energy. Concrete walls and metal buildings essentially act as sound mirrors, potentially creating OSHA violations in areas that should be safe.

Key takeaway: Many noise solutions combine both STC and NRC properties — blocking sound transmission while absorbing reflected energy to prevent reverberation and hot spots.

Noise Regulations and Compliance

Navigating noise regulations requires understanding how federal agencies, states, and local municipalities layer different requirements. Understanding this regulatory hierarchy is essential for keeping projects on track and avoiding costly delays.

The Regulatory Hierarchy

Federal Regulations

At the federal level, OSHA sets workplace noise exposure limits to protect worker health. The current permissible exposure limit (PEL) is 90 dBA for an 8-hour time-weighted average, though NIOSH recommends a more protective 85 dBA limit. These standards apply to all industries but focus on worker protection rather than community noise impacts.

For certain industries, additional federal oversight comes into play. Interstate pipeline projects require Federal Energy Regulatory Commission (FERC) approval, which includes establishing baseline ambient sound levels, predicting construction and operational noise impacts, and proving that mitigation strategies will work.

State-Level Variations

States often fill gaps in federal regulations by addressing community noise impacts. Some states have comprehensive noise control acts, while others delegate authority entirely to local governments. States may also have specific provisions for industries like oil and gas, with different requirements for drilling operations, compressor stations, and processing facilities.

Local Ordinances

Every municipality has its own approach. Some cities focus on maximum decibel levels regardless of time, while others emphasize noise curfew hours. Boston, for example, limits noise to 50 dB from 11 p.m. to 7 a.m. and 70 dB at any time except for permitted construction. Meanwhile, rural areas might have more lenient standards, but don’t assume that means zero oversight.

This complexity creates particular challenges for directional drilling projects that cross multiple jurisdictions, where compliance requirements can change from one neighborhood to the next.

Operator Responsibilities vs. Recommended Actions

Legal Requirements

Operators must meet minimum regulatory standards, but these vary significantly by location and industry. At a minimum, most operations must:

- Comply with OSHA worker exposure limits

- Meet state and local noise ordinances

- Obtain proper permits for construction or operational activities

- Respond to noise complaints through appropriate channels

- Maintain equipment to prevent unnecessary noise

Beyond Compliance: Recommended Actions

Smart operators recognize that meeting minimum requirements isn’t always enough to avoid project delays or community conflicts. Recommended approaches include:

Proactive Assessment: Conducting noise impact studies before problems arise helps identify potential issues and provides documentation for both compliance and community relations.

Baseline Documentation: Establishing ambient noise levels before operations begin protects against future complaints and provides objective data for regulatory discussions. Without this documentation, noise complaints become subjective disputes where neighbors may attribute pre-existing ambient noise to your operation.

Community Engagement: Early communication with neighbors and local officials can prevent minor issues from becoming major problems. Many successful projects establish hotlines for noise concerns and respond quickly to community feedback.

Equipment Selection and Scheduling: Choosing quieter equipment and scheduling noisy operations during peak daytime hours when ambient noise levels are higher can reduce community impact without additional infrastructure costs.

Noise Mitigation Planning: Working with a company that specializes in noise mitigation can be your best bet to prevent stop-work orders and maintain project timelines.

Choosing the Right Noise Control Solutions

Selecting effective noise control is about matching the right technology to your specific acoustic challenges, operational constraints, and regulatory requirements.

Common Noise Control Methods

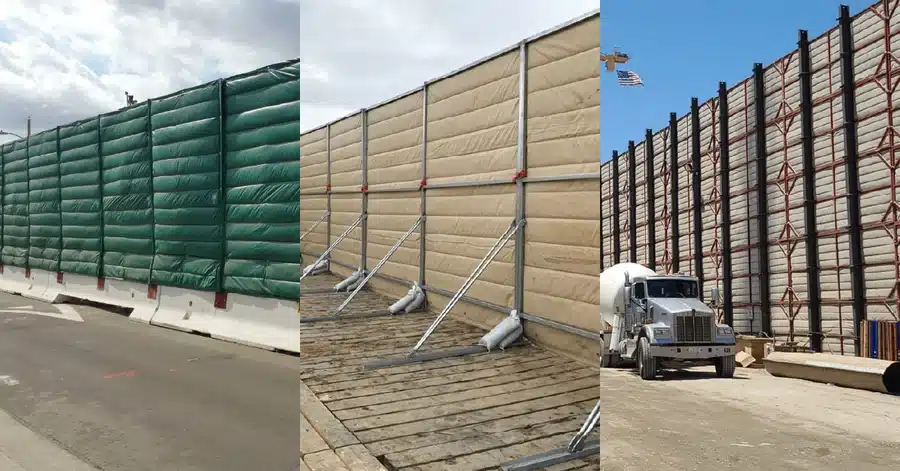

Modular Barrier Systems

These panel-based solutions offer the flexibility that many industrial projects demand. Individual panels connect to form continuous barriers that can be reconfigured as work progresses or equipment moves. The key advantage is adaptability — you can start with a smaller installation and expand as needed, or relocate sections to follow moving operations like pipeline construction.

Equipment-Specific Acoustic Treatments

Rather than surrounding an entire work area, these solutions target individual noise sources. Acoustic wraps for generators, compressor enclosures, and machinery shields can reduce noise at the source before it spreads across your site. This targeted approach often provides better noise reduction per dollar invested, especially for facilities with identifiable primary noise sources.

Engineered Sound Walls

For operations requiring long-term noise control, engineered walls integrate noise mitigation into permanent site infrastructure. These systems can incorporate operational features like equipment access panels, maintenance platforms, and even architectural elements that improve site aesthetics while controlling sound.

Key Selection Criteria

Acoustic Performance Requirements

Before evaluating any product, understand exactly what acoustic challenge you’re solving. A 100 dB diesel generator creates different mitigation requirements than a 90 dB HVAC system, even though both might violate the same 75 dB ordinance. Low-frequency noise from heavy machinery requires different treatment than high-frequency noise from pneumatic tools.

Effective solutions address your specific frequency profile rather than just providing generic noise reduction.

Installation and Operational Flexibility

Consider how your noise control solution integrates with daily operations. Barriers that require crane installation might work for permanent facilities, but create logistical challenges for construction projects. Similarly, solutions that restrict equipment access or interfere with normal workflows can create operational problems that outweigh their benefits.

Environmental Durability

Noise control solutions must withstand the conditions where they’re deployed. Wind loading, UV exposure, and temperature cycling can all affect long-term performance.

| Product | STC Rating | Dimensions | Installation Type | Mobility | Low Freq Performance

(100 Hz) |

Mid Freq Performance

(1000 Hz) |

|||

| TEMPORARY SOUND WALLS | |||||||||

| Temporary Sound Walls | STC-25 / STC-32 | Up to 40′ high | Beam and panel, augered system | Low | 11 dB / 18 dB | 39 dB / 35 dB | |||

| K-Rail Mounted Sound Walls | STC-25 / STC-32 | Up to 20′ high | K-Rail mounted | Low | 11 dB / 18 dB | 39 dB / 35 dB | |||

| FREESTANDING BARRIERS | |||||||||

| SK-8 Sound Barriers | STC-43 | 8’W × 16′-24’H | Freestanding | Forklift movable | 26 dB | 51 dB | |||

| SK-6 Sound Barriers | STC-43 | 6’W × 12’H | Freestanding | Forklift movable | 26 dB | 51 dB | |||

| Portable Acoustic Panels (E812) | STC-25 | 8’W x 12’H | Freestanding | High | 11 dB | 39 dB | |||

| ACOUSTIC BLANKETS | |||||||||

| STC-25 Acoustic Blanket | STC-25 | 8’W x 20’H or 8’W 12’H, custom sizes | Flexible mounting | High | 11 dB | 39 dB | |||

| Quiet World STC-27 Blanket | STC-27 | 8’W × 8′-20’H, custom sizes | Flexible mounting | High | 16 dB | 32 dB | |||

Partnering With Noise Control Professionals

Noise control combines acoustic engineering, regulatory compliance, and practical field experience. Most project managers excel at managing construction, operations, or facilities — but acoustic engineering requires specialized knowledge that’s difficult to develop in-house.

Quality noise control partners bring several advantages beyond product knowledge and can identify potential problems before they become expensive delays.

Avoiding Common Mistakes

Focusing solely on price often leads to solutions that meet minimum specifications but fail in real-world conditions. Noise control is a long-term investment where performance reliability matters more than initial cost.

Ignoring installation requirements can turn a good product into a poor solution. Even small gaps or misplaced barriers can leak sound into neighboring areas or reflect it back at your workers.

Assuming all applications are the same leads to mismatched solutions. A barrier system that works perfectly for a pipeline project might be completely inappropriate for a chemical processing facility, even if both need the same decibel reduction.

Get Expert Help With Your Noise Control Needs

While this handbook provides the foundation for understanding noise challenges and solutions, every project brings unique requirements that benefit from professional expertise.

Environmental Noise Control: Four Decades of Expertise

Since 1993, Environmental Noise Control has specialized in solving complex noise challenges across industries from oil and gas operations to entertainment venues. Our experience spans the complete spectrum of noise control needs — from emergency response to major infrastructure projects.

Our approach combines thorough acoustic assessment with custom-engineered solutions. Rather than offering one-size-fits-all products, we design mitigation strategies specific to your noise signature, site constraints, and regulatory requirements. This precision approach ensures you get effective results without over-investing in unnecessary capabilities.

We maintain one of the largest teams of installation specialists in the nation, along with strategically located inventory to enable rapid deployment when projects face time-critical noise challenges. Whether you need temporary barriers for a construction project or permanent sound walls for a processing facility, we can deliver solutions that keep your operations on track.

Ready To Address Your Noise Challenges?

Don’t let noise issues derail your project or strain community relationships. Our team can assess your specific situation and recommend solutions that protect both your operational success and regulatory compliance.

Contact Environmental Noise Control today to schedule a consultation.